Introduction

In today’s fast-paced industrial landscape, the demand for energy-efficient and precise control solutions is on the rise. One technology that has gained significant popularity is the Abb VFD (Variable Frequency Drive). This article explores the capabilities, benefits, and applications of Abb VFDs, highlighting how they contribute to enhancing efficiency and control in various industrial sectors.

Table of Contents

- Understanding VFDs

- The Functionality of Abb VFDs

- Benefits of Abb VFDs

- Applications of Abb VFDs

- Factors to Consider When Choosing an Abb VFD

- Installation and Maintenance Tips

- Future Trends in Abb VFD Technology

- Conclusion

- FAQs (Frequently Asked Questions)

Understanding VFDs

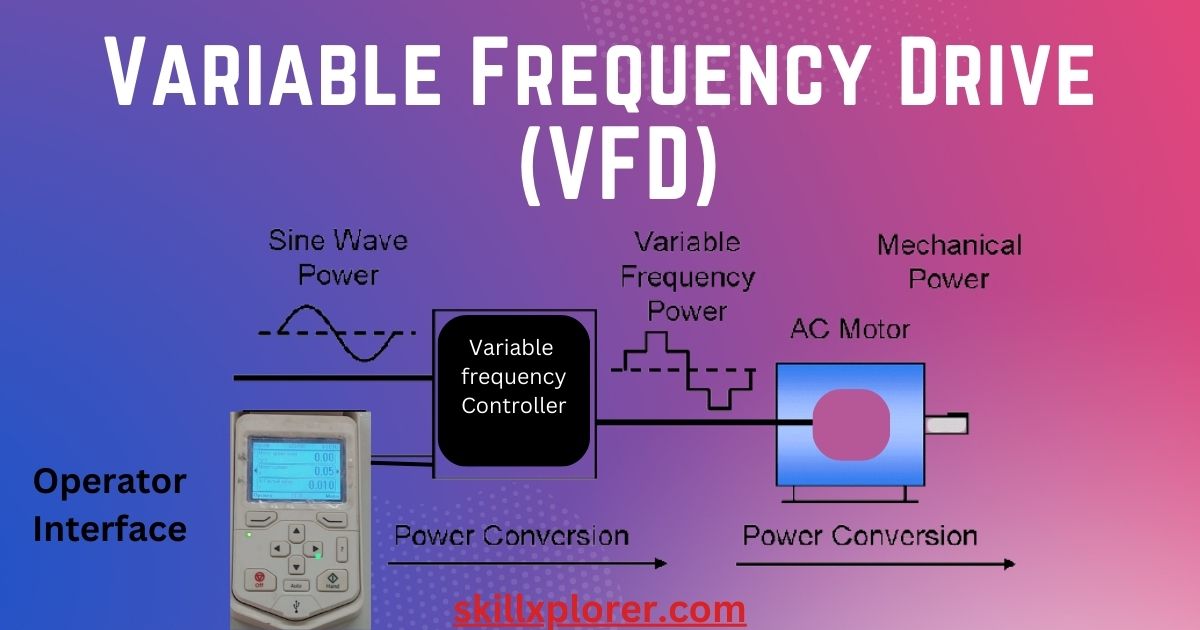

Before delving into the specifics of Abb VFDs, let’s first understand what Variable Frequency Drives are. VFDs are electronic devices used to control the speed and torque of electric motors. By varying the frequency and voltage supplied to the motor, VFDs enable precise control over motor speed, resulting in improved energy efficiency and performance.

The Functionality of Abb VFDs

Abb VFDs are renowned for their robust functionality and advanced features. They consist of three main components: an AC input power supply, a rectifier that converts AC power to DC, and an inverter that converts DC power back to AC with adjustable frequency and voltage. This flexible system allows for seamless control of motor speed and torque, catering to the specific requirements of different applications.

Benefits of Abb VFDs

- Energy Efficiency: Abb VFDs optimize energy consumption by regulating motor speed based on actual load requirements, eliminating energy wastage during low-demand periods.

- Improved Motor Performance: With precise control over motor speed, Abb VFDs minimize mechanical stress, reduce wear and tear, and extend the lifespan of motors.

- Enhanced Process Control: The ability to adjust motor speed in real-time enables improved control over industrial processes, leading to higher accuracy, productivity, and quality.

- Cost Savings: By reducing energy consumption, improving motor performance, and minimizing downtime, Abb VFDs contribute to significant cost savings over time.

Applications of Abb VFDs

Abb VFDs find applications across a wide range of industries, including:

- Manufacturing: In manufacturing facilities, Abb VFDs regulate motor speed in conveyor systems, pumps, fans, and other equipment, ensuring optimal energy usage and precise control over production processes.

- HVAC (Heating, Ventilation, and Air Conditioning): Abb VFDs enhance the energy efficiency of HVAC systems by dynamically adjusting fan and pump speeds based on changing thermal loads, resulting in reduced energy consumption and improved comfort.

- Water and Wastewater Treatment: Abb VFDs play a crucial role in water and wastewater treatment plants, where they control motor speeds in pumps, mixers, and aeration systems, facilitating efficient and reliable operations.

- Renewable Energy: Abb VFDs are utilized in renewable energy systems, such as wind turbines and solar tracking systems, enabling optimal power generation and seamless integration with the electrical grid.

Factors to Consider When Choosing an Abb VFD

When selecting an Abb VFD for your specific application, consider the following factors:

- Power and Voltage Ratings: Ensure that the VFD can handle the power and voltage requirements of your motor.

- Enclosure Type: Depending on the installation environment, choose the appropriate enclosure type to protect the VFD from dust, moisture, and other potential hazards.

- Control and Monitoring Features: Look for VFDs with user-friendly interfaces, advanced diagnostics, and remote monitoring capabilities to simplify operation and maintenance.

- Compliance and Certification: Verify that the Abb VFD meets industry standards and certifications to ensure safety and reliability.

Installation and Maintenance Tips

To maximize the performance and longevity of your Abb VFD, consider these installation and maintenance tips:

- Proper Cooling and Ventilation: Ensure sufficient airflow around the VFD to prevent overheating.

- Regular Inspections: Perform periodic visual inspections, checking for loose connections, abnormal heat, or signs of wear.

- Scheduled Maintenance: Follow the manufacturer’s guidelines for routine maintenance tasks, such as cleaning, lubrication, and firmware updates.

- Training and Documentation: Provide proper training to personnel responsible for VFD operation and maintenance, and keep comprehensive documentation for reference.

Future Trends in Abb VFD Technology

The field of Abb VFD technology is constantly evolving. Some future trends to watch out for include:

- Integration with IoT: VFDs will become increasingly connected, allowing for seamless integration with Industrial Internet of Things (IIoT) platforms for enhanced data analysis, predictive maintenance, and automation.

- Advanced Energy Optimization: The next generation of Abb VFDs will incorporate advanced algorithms and machine learning capabilities to further optimize energy usage and reduce carbon footprint.

- Enhanced Fault Detection: VFDs will feature improved fault detection and diagnostics, enabling proactive maintenance and minimizing downtime.

Conclusion

Abb VFDs have revolutionized the industrial sector by providing efficient and precise control over electric motors. Their energy-saving capabilities, enhanced motor performance, and wide range of applications make them a valuable asset for industries worldwide. By incorporating Abb VFDs into their operations, businesses can achieve greater efficiency, cost savings, and improved process control.

FAQs (Frequently Asked Questions)

1. Are Abb VFDs compatible with different motor types?

Yes, Abb VFDs are designed to work with various motor types, including induction motors and permanent magnet motors.

2. Can Abb VFDs be retrofitted into existing systems?

Yes, Abb VFDs can be retrofitted into existing systems, provided they meet the necessary compatibility requirements.

3. How do Abb VFDs contribute to energy savings?

Abb VFDs regulate motor speed based on actual load requirements, reducing energy consumption during low-demand periods and improving overall energy efficiency.

4. Can Abb VFDs be used in hazardous environments?

Yes, Abb VFDs are available in enclosures that comply with hazardous area classifications, allowing for safe operation in such environments.