Introduction of Piping Flange

A piping flange is a mechanical component used in the construction of piping systems to connect pipes, valves, pumps, and other equipment together. It provides a means for joining sections of pipe and allows for easy assembly, disassembly, and maintenance of the system.

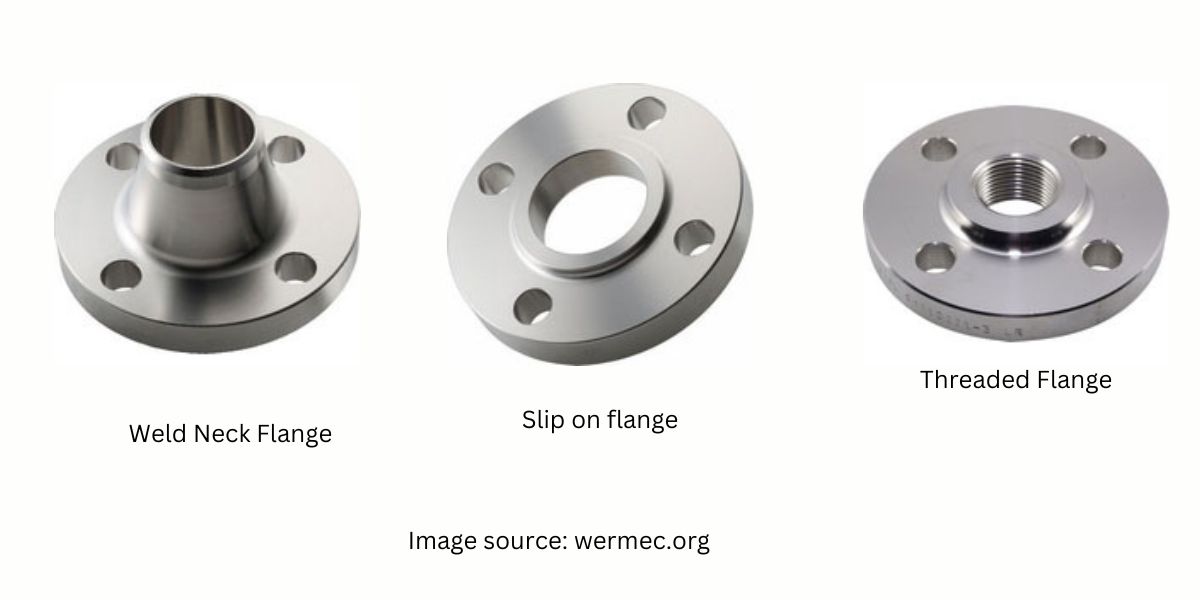

Flanges are typically circular and have a flat sealing surface, which allows for easy alignment and attachment. Flange are classified based on design and connection.

Types of flanges in piping

- Weld Neck flange: This type of flange has a long tapered hub that extends from the flange and is welded to the pipe. It provides high strength and structural integrity. The flange type that will be welded to a pipe or fitting with a single full penetration, V weld (Butt weld) is called a Weld Neck Flange.

- Slip on flange: These type of flange always connected to pipes by one or two fillet welding.

- Socket weld Flange: This type flange usually use for leak proof joint, pipe inserted into the socket of the flange and then fillet weld from outside.

- Threaded flange: This type flange has a internal thread that match the external threads of pipe. the threaded flange screwed into the onto the pipe, creating leak proof joint.

- Lap joint flange: Lap joint has two main components, the stub in and backing flange. The lap joint flange assembly by sliding the stub end into the banking, its commonly use in low pressure service.

- Blind flange: A blind flange primarily to cap or close off the end of pipe section.

Flange Class, Flange Schedule

As we know that flange rating or class depends on pressure – temperature. It indicates maximum allowable pressure and temperature which the flange can safely operate.

Such as Class 150, Class 300, Class 600, Class 900, Class 1500, Class 2500. The higher number of class means the higher pressure and temperature rating.

Flange rating and standard

Flange are fabricated according to various standard in piping system.

- ASME/ANSI B16.5: American Society of Mechanical Engineer, This standard mainly use in United State and specifies dimensions, pressure – temperature rating for pipe flange and fittings.

- EN1092: This is the European Standard for flange.

Piping Flange Questions and Answers

1. What are the 3 most common flange types?

The most common flange type is 1.Weld Neck flange (Mostly use in Oil and Gas, Refineries, Petrochemical plant)

2. Slip on flange?

These type of flange always connected to pipes by one or two fillet welding. (mostly use in HVAC piping)

2. What is the main function of pipe flanges?

Pipe flanges are primarily used to connect two sections of pipe or valve equipment, making it easier to maintain, assemble, and repair them.

3. What is Blind flange?

A blind flange is primarily used to cap or close off the end of a pipe section.

4. Why is it called a flange?

The term “flange” comes from Old French and refers to a projecting or protruding part.

5. What is the flange thickness?

The thickness of a flange is determined by the flange class.

6. What is the material between flange?

In between the flange we are using a gasket. A gasket is sealing material placed between flanges, it creates seal, leak proof.

7. How do you identify a flange?

When identifying a flange, you can start by checking for information such as flange types, material coding, and size. Additionally, it’s important to determine the outer diameter, inner diameter, number of bolt holes, bolt hole diameter, and the bolt circle diameter as crucial measurements.

8.What is the most commonly used flange?

The weld neck flanges, including long weld necks, are considered to be the most used type of flange in the industry.

The most commonly used flange in the industry is the weld neck flange, including long weld necks.

9. why flange is used in piping?

It provides a means for joining sections of pipe and allows for easy assembly, disassembly, and maintenance of the system.

Thank You

Also Read:

Confined Space Safety Hazards and Precautions

RACE Fire Safety: Responding to Fire Emergencies

Abb VFD: Enhancing Efficiency and Control in Industrial Applications

Plumbing Interview Questions and Answers

Piping Interview Questions and Answers